September 11-14, 2023|#FABTECH2023

FABTECH Chicago

Driving Manufacturing Forward

JOIN US IN CHICAGO!

Welcome to FABTECH

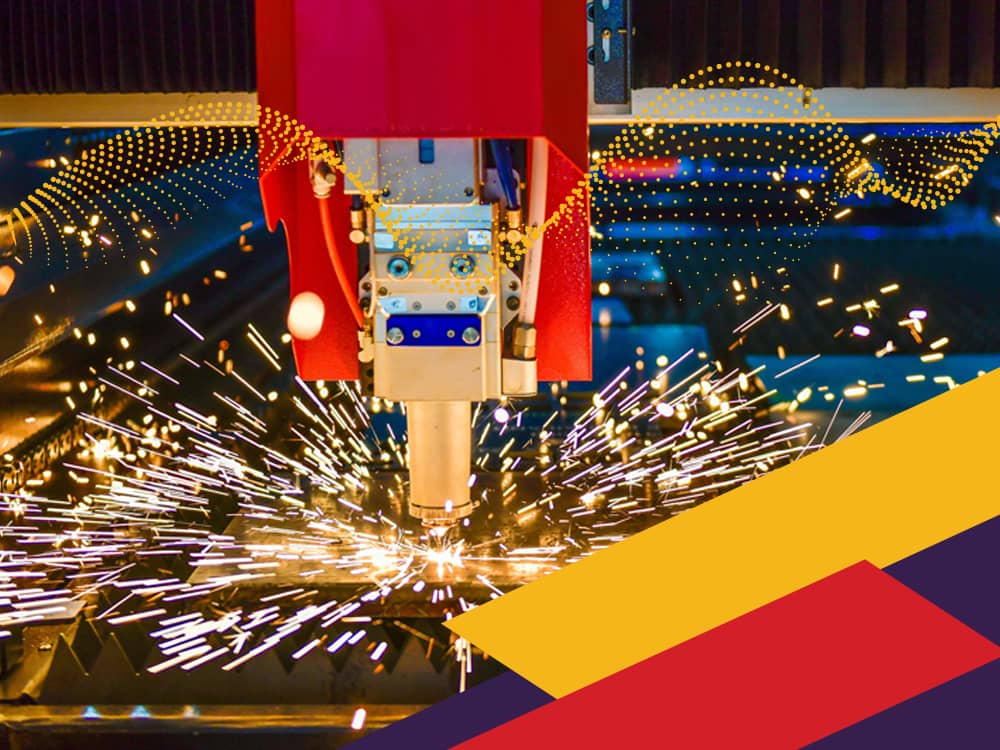

And see the advanced manufacturing solutions that bring new levels of productivity and efficiency to your operations. FABTECH gives you the tools, technology, and thought leadership to stay ahead of the competition.

floorplan donwloadEXPO BASICS

Welcome to FABTECH 2023 Registration

What is Fabtech?

FABTECH is the largest US metal industry exhibition, showcasing advancements in metal processing. Experience this premier event at McCormick Place from September 11-14, 2023. Meet 1,400+ suppliers, explore the latest products, enhance productivity, and find solutions for your metal needs. Yunsing Industrial Co LTD. offers innovative cold roll forming solutions and technical support. Stay ahead in the industry and boost profitability.

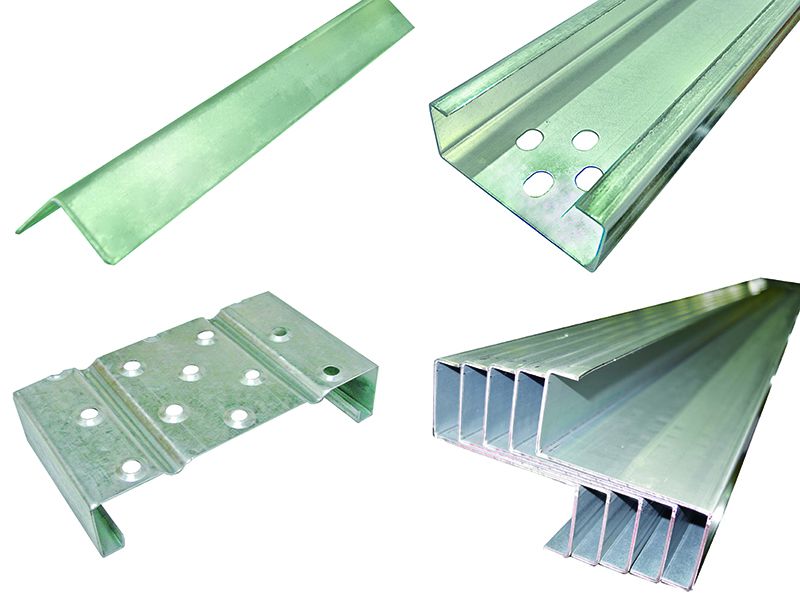

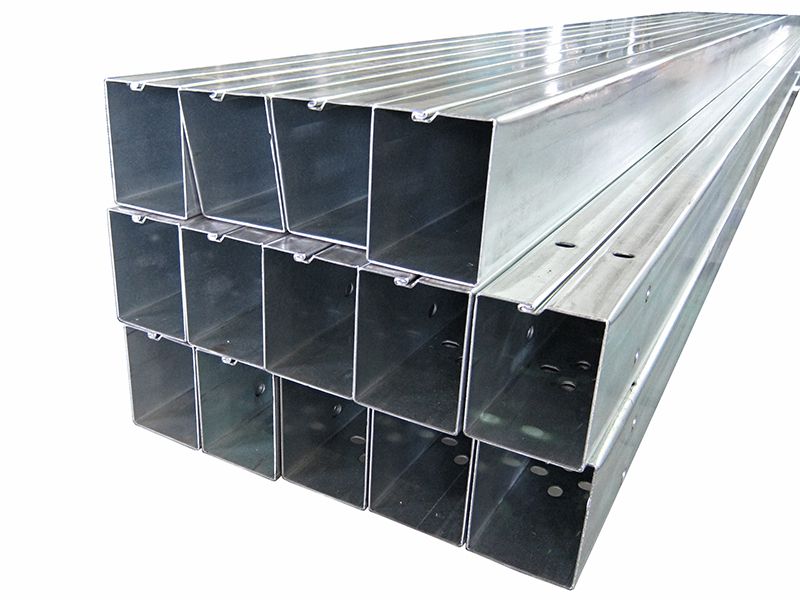

What can you discover on Yunsing?

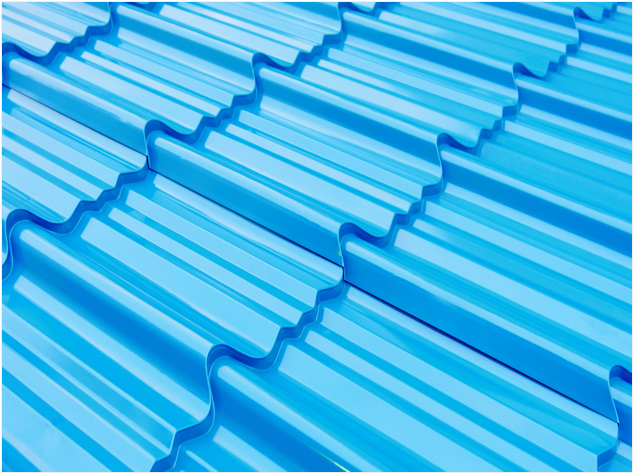

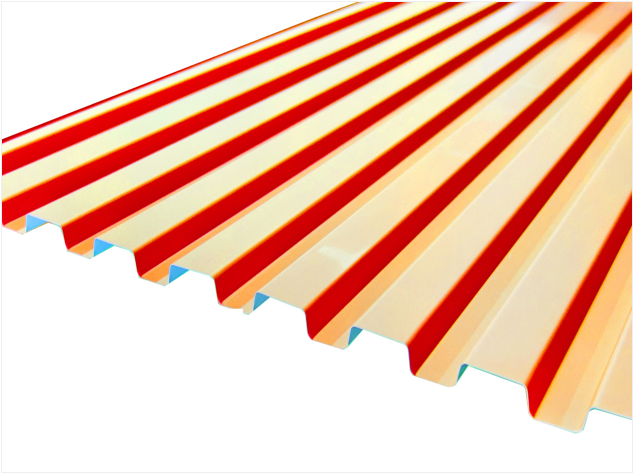

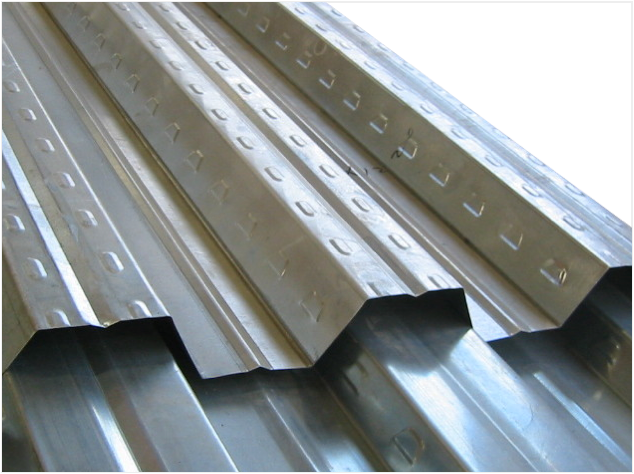

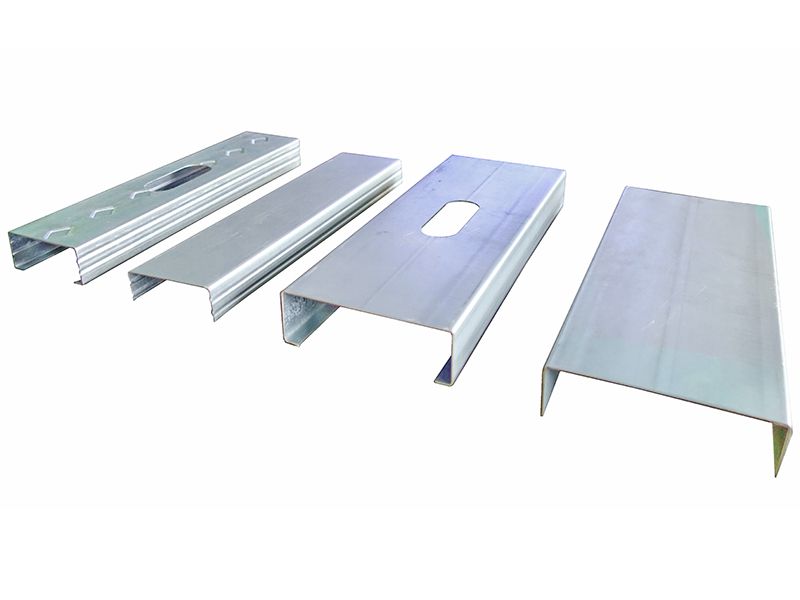

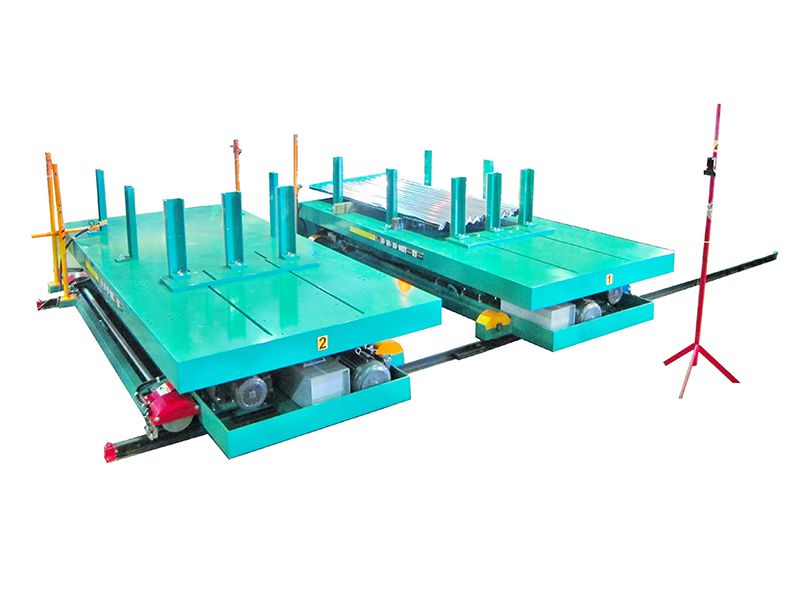

As a leading manufacturer, Yunsing specialized in automatic cold roll forming machines and products. We have a range of innovative products available, including customized machines such as Roofing & Wall Cladding, Corrugated with Flying Shear, Stepped Tile, Ridge Capping, Floor Decking, C/Z-Purlin, Stud & Truss, Roller Door & Shutters, Slitting & Shearing Line, which we will offer and showcase at FABTECH.

Our advantages

.The leading provider of cold roll forming machines

.100% manufactured in Taiwan

.exports reach over 60 countries

.OEM & ODM Manufacturer

.Over 50 years of experience in manufacturing

.24-hour technical support through immediate online methods